The meat and potatoes of his theory is simple mathematics. Here is more from the article and Tibbits’ theory:

Tibbits’ answer: Geometry.

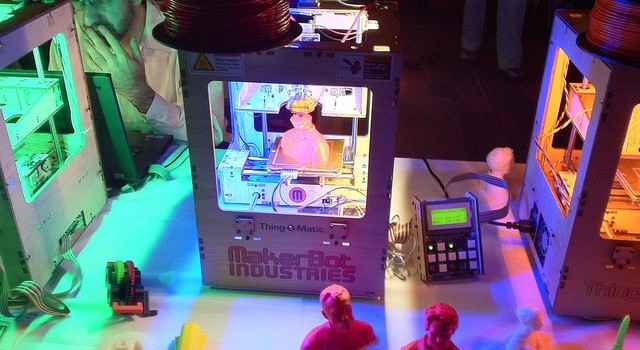

With a 3D printer, an operator plugs in a virtual blueprint for an object, which the printer uses to construct the final product layer by layer. To make something “4D,” though, Tibbits feeds the printer a precise geometric code based on the object’s own angles and dimensions but also measurements that dictate how it should change shape when confronted with outside forces such as water, movement or a change in temperature.

In short, the code sets the direction, the number of times and the angles at which a material can bend and curl. When that object is confronted with a change in environment, it can be stimulated to change shape. Pipes, for instance, could programmed to expand or shrink to help move water; bricks could shift to accommodate more or less stress on a given wall.

photo by Kyle Pearce